Advantages

1. Smooth mirror-like surface.

2. Seamless, non-dusty and easy to clean.

3. Solvent-free and environmental.

4. Corrosion-resistance dense surface.

5. A large range of colors for choice.

Technical Data:

Drying time |

|

Touch dry: | 8-12 hours |

Hard dry: | 2 days |

Compressive strength (Mpa): | ≥85 |

Impact resistance strength (Kg•cm): | 50 |

Flexural strength (Mpa): | ≥7 |

Tensile strength (Mpa): | ≥9 |

Shore hardness: | ≥85 |

Abrasion resistance(750g/500r, CS-17, g) | ≤0.06 |

Service life: | 25years |

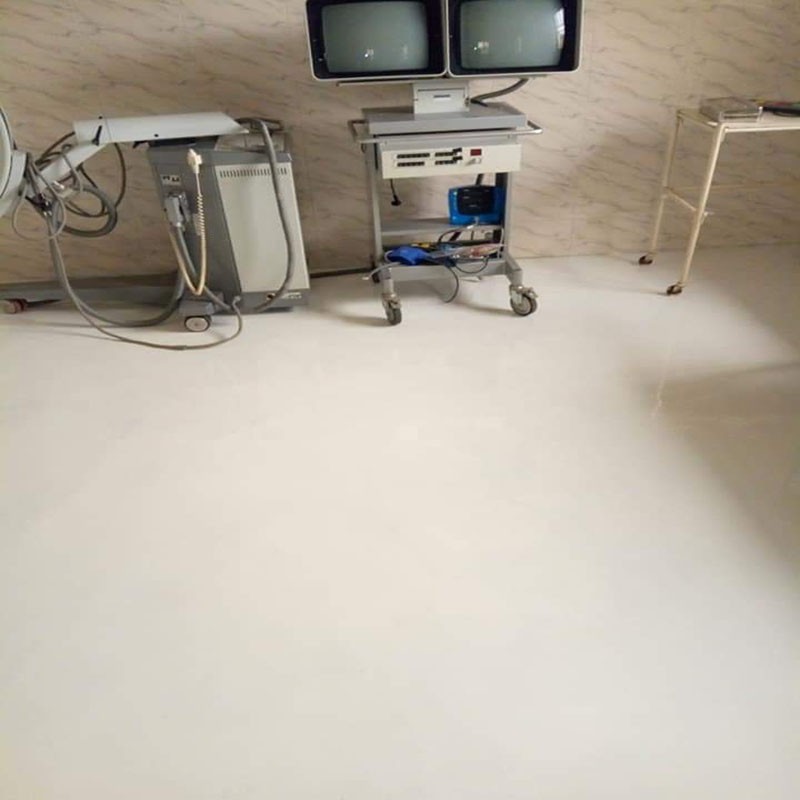

Where to Use:

It is mainly used for concrete surface where has compression & wearing resistance and anti-dust and corrosion requirement, such as Car Parking,ndustry workshop, office, warehouse, foodstuff factory etc.

Application instructions:

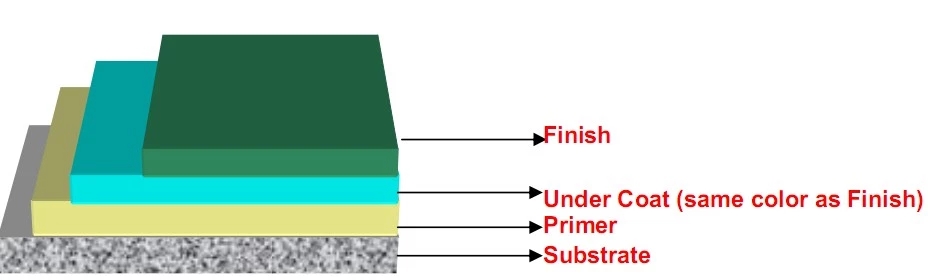

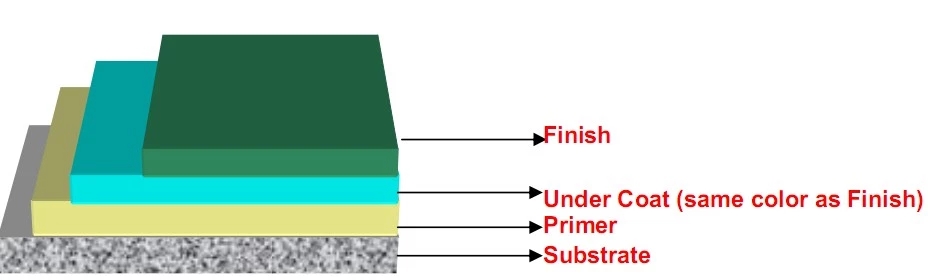

Surface preparation | Correct substrate preparation is critical for optimum performance. Surface should be sound, clean, dry and free from loose particles,oil,grease,and other contaminants. |

Primer | Prepare a barrel, pour paint and hardener Stir the mixture well and then apply it with roller or trowel. The reference consumption is 0.15kg/m².The main purpose of this primer is to seal the substrate completely and avoid air-bubbles in the body coat. A second coat may be required depending on the oil absorption condition of substrate. The recoat time is about 8 hours. |

Inspection standard for the primer: even film with certain brightness. |

Undercoat | Mix paint and hardener then add quartz powder (1/2 of the mixture of A and B) into the mixture, stir it well and apply with trowel. The consumption quantity of A and B is 0.5kg /sqm. You can do it one coat at one time or two coats at two times. In the second case, the application interval is about 8 hours at 25 degrees. Sand the first layer, clean it and then apply the second layer. After the whole application, wait another 8 hours, grind it, clean the sanding dust and then continue the next procedure. |

Inspection standard for the undercoat: Non-sticky to hand, no softening, no nail print if you scratch the surface |

Top coat | Mix paint and hardener and then apply the mixture with spatula. The consumption quantity is 1.0kg/sqm. |

Maintenance | 5-7 days. Don’t put the floor into use or wash it with water or other chemicals. |

Payment Method And After-Sales Service:

1. The company's payment method supports T/T or Western Union

2. After delivery, our company has professional after-sales customer service personnel to track the in-transit status of products for you, so as to ensure the safety and fast delivery of products to customers.

3. Senior engineers can enjoy a full range of quality one-to-one service for free and give professional advice in the production and operation process. The company's professional engineers can also according to customer requirements, research and development of a variety of different performance of products, curing conditions, temperature grades, color, surface gloss, transparency, hardness and other aspects, to make appropriate deployment, to meet customer's different needs!

4. Our company promises that if there is any quality problem in the normal operation, we will replace the goods unconditionally, and our company will bear the freight incurred on the way.