In modern shipping and marine engineering, ships, offshore platforms, submarine facilities, etc. often need to face extremely harsh marine environments, which include strong ultraviolet rays, high humidity, salt spray, seawater corrosion, wind and waves, etc. These factors will not only cause aging, corrosion and damage to the materials, but may also affect the normal operation and service life of the facilities.

Therefore, coatings suitable for marine environments are particularly important. Among them, marine-grade epoxy resin paint, as a protective coating with superior performance, is widely used in marine engineering due to its excellent corrosion resistance, weather resistance, adhesion and excellent physical and chemical properties.

This article will discuss in detail the definition, characteristics, composition, application fields, usage methods and advantages and disadvantages of marine-grade epoxy resin paint in actual operation, to help users better understand the value of this paint and its importance in the marine environment.

What is marine-grade epoxy resin paint?

Marine-grade epoxy resin paint refers to high-performance epoxy resin paint specially designed for marine environments. This kind of paint is based on epoxy resin, with various additives, fillers and curing agents added. After strict formula design, it has excellent corrosion resistance, moisture resistance, salt spray resistance and UV resistance. The purpose of marine-grade epoxy resin paint is to protect ships, offshore platforms, marine facilities, etc. from the erosion of harsh conditions such as seawater, moisture and salt spray, and extend the service life of these facilities.

1. The principle of epoxy resin paint

Epoxy resin paint is a type of paint formed by the reaction of epoxy resin and curing agent. Epoxy resin itself has good adhesion, chemical corrosion resistance and wear resistance, and is suitable for a variety of harsh environments. When epoxy resin reacts with curing agent, a cross-linked network structure is formed, which gives epoxy resin paint stronger mechanical strength and corrosion resistance.

Marine-grade epoxy resin paint is based on epoxy resin paint, and its oxidation resistance and salt resistance in marine environment are enhanced by special additives and fillers. Compared with general epoxy resin paint, marine-grade epoxy resin paint can more effectively cope with the harsh challenges in the marine environment.

What are the characteristics of marine-grade epoxy resin paint?

1. Excellent anti-corrosion performance

Salt water, humidity, and marine organisms in the marine environment are extremely corrosive to metals, steel, and other materials. Marine-grade epoxy resin paint uses high-quality epoxy resin and special anti-corrosion ingredients to give it extremely strong anti-corrosion ability, which can effectively prevent metal materials from rusting and corroding in seawater environments. Its strong anti-corrosion ability can usually cope with long-term seawater immersion and salt spray erosion.

2. Excellent moisture resistance and salt spray resistance

The marine environment has the characteristics of high humidity, and the penetration of moisture can easily cause the coating layer to peel off or deteriorate. Marine-grade epoxy resin paint is specially designed to improve moisture resistance and salt spray resistance. It can still maintain stable performance in a long-term humid environment and is not easily eroded by moisture. In addition, it can also effectively resist the invasion of salt spray and prevent salt spray from damaging the coating and substrate.

3. Strong adhesion

Marine-grade epoxy resin paint has extremely strong adhesion and can adhere firmly to various metal surfaces, concrete surfaces and other substrates to ensure that the coating does not fall off or fall off. It can adapt to the complex operating environment of the bottom of the ship or other marine facilities, ensuring the long-term stability of the coating.

4. High temperature resistance

Although the temperature changes in the marine environment are relatively mild, in some cases, the outer surface of the equipment or hull will be affected by high temperature. Marine-grade epoxy resin paint can maintain its stability and durability at a certain high temperature and adapt to changes in thermal expansion and contraction.

5. Anti-ultraviolet radiation in the marine environment can cause aging and fading of the coating layer, especially in marine facilities and ships exposed to the sun for a long time. Therefore, marine-grade epoxy resin paint usually adds anti-ultraviolet ingredients, which can effectively prevent the aging and fading of the coating and maintain the beauty and protective function of the coating.

What are the components of marine-grade epoxy resin paint?

Marine-grade epoxy paint is composed of a variety of ingredients, mainly including the following categories:

1. Epoxy resin

Epoxy resin is the main base material of the paint, which determines the basic properties of the paint, such as corrosion resistance and adhesion. The molecular structure of epoxy resin has high chemical stability and shows good chemical corrosion resistance in the marine environment.

2. Curing agent

The curing agent is a substance that reacts with epoxy resin to form a solid coating, which determines the hardness, adhesion and weather resistance of the paint film. The reaction of the curing agent with the epoxy resin makes the coating stronger and provides waterproof and corrosion resistance.

3. Pigments and fillers

Pigments are usually used to improve the hiding power and aesthetics of the paint layer, while fillers increase the thickness, hardness and wear resistance of the paint. Some mineral components in the filler can increase the salt spray resistance of the coating.

4. Additives and additives

In order to further improve the performance of the paint, some special additives and additives are often added during the production process, such as UV inhibitors, plasticizers, leveling agents, etc. These ingredients help to improve the weather resistance, fluidity, construction performance, etc. of the paint.

What are the application fields of marine-grade epoxy resin paint?

Marine-grade epoxy resin paint is widely used in a variety of marine environments and facilities, mainly including the following fields:

1. Ship primer

Marine-grade epoxy resin paint is often used for ship primer coating, especially large ocean-going ships such as tankers, container ships, and bulk carriers. By coating this epoxy resin paint with excellent anti-corrosion performance, the hull can better resist the erosion of seawater, extend the service life of the ship, and reduce the attachment of biological organisms on the bottom of the ship and reduce fuel consumption.

2. Offshore oil platforms and facilities

Offshore oil platforms, oil and gas field facilities and related equipment are exposed to the marine environment for a long time, so the anti-corrosion requirements are extremely high. Marine-grade epoxy resin paint plays a vital role in the coating of these facilities, ensuring that these facilities can effectively resist the corrosion of seawater, the erosion of salt spray and the damage of ultraviolet rays for a long time.

3. Marine engineering facilities

In addition to ships and oil platforms, marine-grade epoxy resin paint is also widely used in other facilities in marine engineering, such as submarine pipelines, offshore wind power equipment, port facilities, etc. These facilities usually need to be in the marine environment for a long time, so their anti-corrosion coatings must have excellent durability and corrosion resistance.

4. Marine buildings and bridges

With the increasing development of marine engineering, many ports, ocean bridges, docks and other construction facilities also need to face the erosion of seawater and salt spray. Marine-grade epoxy resin paint is widely used as a coating material in these facilities to help enhance their structural stability and corrosion resistance.

What is the construction method of marine-grade epoxy resin paint?

The construction method of marine-grade epoxy resin paint is similar to other coatings, but considering the particularity of its use environment, special attention should be paid to the following points during construction:

1. Surface preparation

Before painting, the surface of the substrate should be thoroughly cleaned to remove impurities such as oil, rust, and old paint. For metal surfaces such as steel, sandblasting or brushing is usually required to improve the adhesion of the paint film.

2. Coating conditions

When applying the paint, ensure that the temperature and humidity are appropriate. The painting environment temperature should be between 10℃ and 35℃. Too high or too low humidity may affect the drying and curing of the coating.

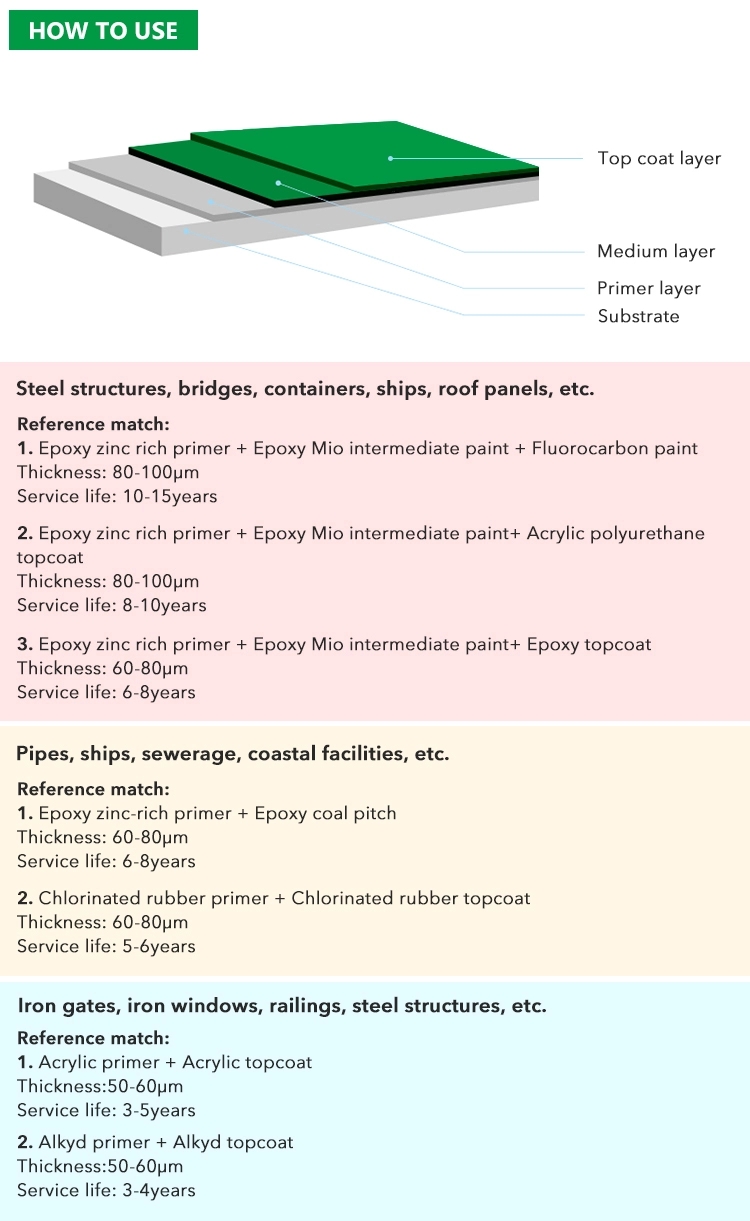

3. Coating thickness

Usually, marine-grade epoxy resin paint requires multiple layers of coating, the first layer is primer, followed by mid-coat and topcoat. The coating thickness of each layer depends on specific requirements, and the generally recommended coating thickness is 50μm to 150μm.

4. Drying and curing

The drying time and curing time of the coating should be determined according to the actual situation. Generally, marine-grade epoxy resin paint takes 24 to 48 hours to fully cure at room temperature. The coating can only be put into use after it is fully cured.

How can international buyers procure products from Huaren Chemical?

Our global procurement process is streamlined for buyers seeking high-quality coatings from a trusted China supplier. With an annual output exceeding 20,000 tons, 30 paint production lines and 6 resin lines, we can support both single orders and large wholesale purchasing. To buy from us, simply request a quote through our website or sales team, specifying your desired coat type (epoxy, acrylic, alkyd, phenolic, water based, nitrocellulose, chlorinated rubber, or anti-corrosion).

We will provide customized quotes showing prices, MOQ, packaging, shipping options, and any ongoing promotions. You benefit from factory-direct pricing, bulk order discounts, and reliable supply chain.