Protective Enamel Paint is a type of paint known for its excellent protective properties and aesthetic effects. It is widely used on various metal and non-metal surfaces, providing multiple protection functions such as wear resistance, corrosion resistance and weather resistance.

This article will explore the main uses of protective enamel paint and analyze its specific applications and advantages in different fields.

What are the properties of protective enamel paint?

Before exploring its specific uses, it is important to understand the basic properties of protective enamel paints. Protective enamel paint is usually composed of high-quality resins, pigments and additives, and is made through a special processing technology, with the following notable features:

1. High hardness: Enamel paint has a high hardness and can effectively resist external mechanical damage such as scratches and impacts.

2. Corrosion resistance: It can prevent corrosive substances such as acid, alkali and salt from corroding the substrate and is suitable for various harsh environments.

3. Weather resistance: Under natural environments such as ultraviolet rays, wind and rain, enamel paint can maintain its physical and chemical properties for a long time and is not easy to fade or powder.

4. Aesthetics: Enamel paint has a smooth surface and bright colors, and can provide high-quality decorative effects.

What is Protective Enamel Paint used for?

Uses of protective enamel paint:

● Industrial equipment protection

1. Chemical equipment

2. Power plant equipment

3. Oil and gas equipment

● Building and infrastructure protection

1. Steel structure building

2. Municipal facilities

● Household and daily necessities protection

1. Home appliances

2. Interior decoration

● Transportation protection

1. Cars and motorcycles

2. Ships and water vehicles.

Industrial Equipment Protection

1. Chemical equipment:

Chemical equipment is often exposed to various corrosive media, such as acids, alkalis, salts and organic solvents. These media are extremely corrosive to the metal parts of the equipment, seriously affecting the service life and safety of the equipment. Protective enamel paint can effectively isolate chemical media and prevent metal surfaces from corrosion.

Specific applications:

● Inner and outer walls of the tank: Enamel paint can be applied to the inner and outer walls of the tank to prevent the internal medium from corroding the tank, while protecting the outside of the tank from environmental influences.

● Pipes and valves: Applying enamel paint on chemical pipes and valves can effectively extend their service life and reduce leakage and damage caused by corrosion.

2. Power plant equipment:

Power plant equipment, such as boilers, cooling towers and turbines, are exposed to high temperature, high pressure and humidity for a long time, and are very susceptible to corrosion and wear. Protective enamel paint can provide excellent high temperature resistance and anti-corrosion performance, ensuring the stable operation of power generation equipment.

Specific applications:

● Boiler outer wall: Enamel paint can be used to protect the outer wall of the boiler to prevent erosion by high-temperature flue gas and condensed water.

● Inner and outer surfaces of cooling tower: The inner and outer surfaces of the cooling tower are coated with enamel paint, which can effectively prevent corrosion from water and chemicals and extend the life of the equipment.

3. Oil and Gas Equipment:

Oil and gas equipment, such as drilling platforms, oil storage tanks and oil pipelines, are exposed to harsh environments such as oceans and deserts for a long time and face severe corrosion challenges. Protective enamel paints offer excellent salt spray and corrosion resistance for reliable protection.

Specific applications:

● Offshore drilling platform: Enamel paint can be used to protect the steel structure of the drilling platform to resist corrosion from seawater and salt spray.

● Oil pipeline: Coating the outer surface of the oil pipeline with enamel paint can prevent the pipeline from being corroded by corrosive substances in the soil and atmosphere.

Building and infrastructure protection

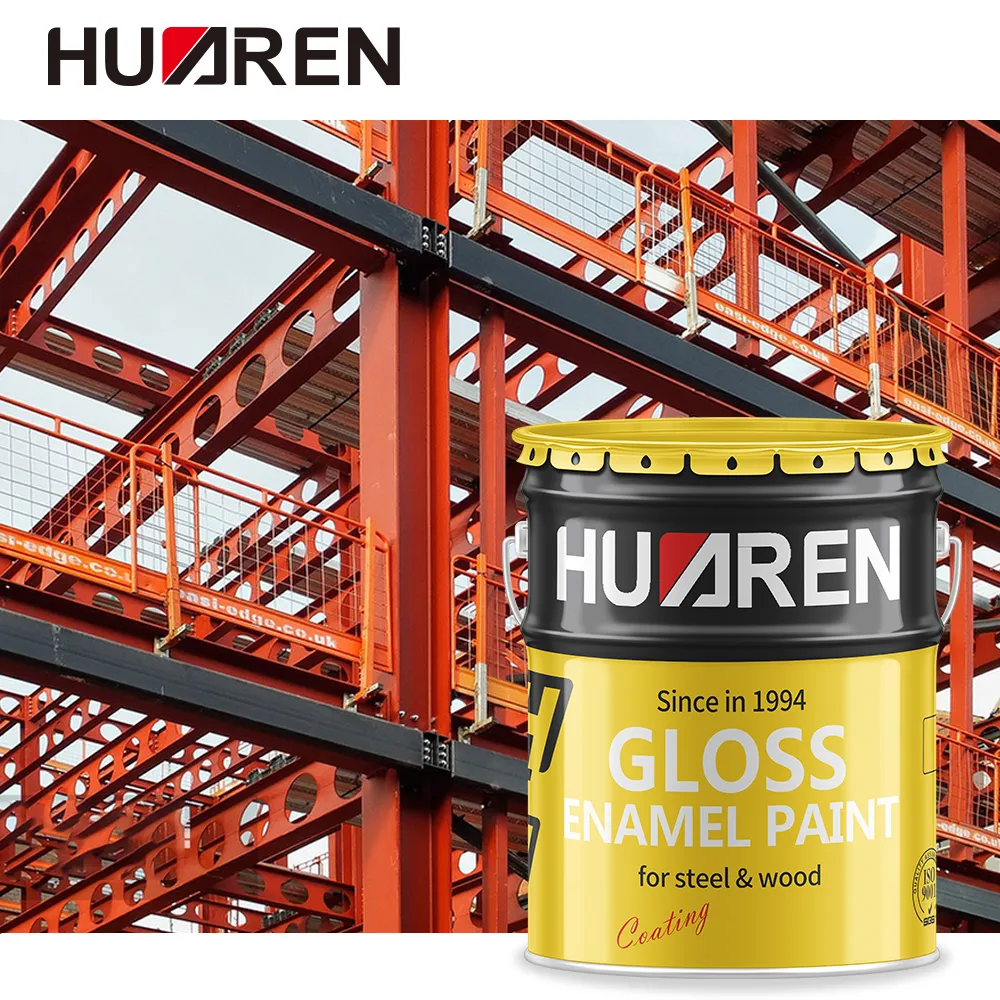

1. Steel structure building:

Steel structures are widely used in modern buildings, such as bridges, towers and factory buildings. These steel structures are exposed to the atmospheric environment and are susceptible to oxidation and corrosion. The high weather resistance and anti-corrosion properties of protective enamel paints make them ideal for the protection of steel structures.

Specific applications:

● Bridges: Enamel paint is applied to the steel structure of bridges to prevent corrosion from wind, rain and industrial pollutants, thus extending the service life of the bridges.

● Steel frames of high-rise buildings: Steel frames of high-rise buildings are coated with enamel paint, which not only provides anti-corrosion protection but also enhances the aesthetics of the building.

2. Municipal facilities:

Municipal facilities such as street lights, guardrails and public transportation facilities are exposed to the outdoor environment for a long time and are easily damaged by natural and man-made factors. Protective enamel paint provides long-term protection and reduces maintenance costs.

Specific applications:

● Light poles and guardrails: Light poles and guardrails coated with enamel paint can prevent corrosion and rust, maintaining the beauty and functionality of the facilities.

● Public transportation facilities: Public transportation facilities such as bus stops, shelters and subway entrances can be coated with enamel paint to enhance their durability and anti-fouling properties.

Household and daily necessities protection

1. Household appliances:

Household appliances such as refrigerators, washing machines and microwave ovens often need to protect their casings and internal parts from oxidation and corrosion. Protective enamel paint not only provides good protection, but also increases the beauty and durability of the appliance.

Specific applications:

● Refrigerator liner: The refrigerator liner is coated with enamel paint, which can prevent erosion by food residues and moisture and is easy to clean.

● Washing machine shell: The washing machine shell is coated with enamel paint to prevent rust in a humid environment and extend its service life.

2. Interior decoration:

Protective enamel paint is also widely used in interior decoration, such as furniture, lamps and decorations. It not only provides protection but also adds decorative effect.

Specific applications:

● Metal furniture: Enamel paint is applied on the surface of metal furniture to prevent scratches and corrosion, and maintain the smoothness and beauty of the furniture.

● Lamps and decorations: Enamel paint applied to lamps and metal decorations not only provides protection but also enhances the decorative effect, making them more beautiful.

Vehicle protection

1. Cars and motorcycles:

The metal parts of cars and motorcycles, such as the body, chassis and engine, are often exposed to various harsh environments and are susceptible to corrosion and wear. Protective enamel paints provide comprehensive protection and extend the service life of your vehicle.

Specific applications:

● Body painting: Car and motorcycle bodies are coated with enamel paint to protect them from sunlight, rain and chemicals, keeping them looking bright.

● Chassis protection: The chassis is coated with enamel paint to prevent corrosion to the chassis by mud, sand and salt, thereby enhancing the durability of the vehicle.

2. Ships and watercraft:

Ships and water vehicles, such as yachts, cargo ships and ferries, travel in water for a long time and are easily corroded by seawater and fresh water. Protective enamel paint can provide excellent waterproof and anti-corrosion properties, ensuring the safety and service life of the ship.

Specific applications:

● Hull: The hull is coated with enamel paint to prevent corrosion from seawater and biological attachment, keeping the hull intact.

● Cabin interior: The interior of the cabin is coated with enamel paint to prevent corrosion and mildew in a humid environment and keep the cabin clean and dry.

Huaren Chemical Industry Co., Ltd. is a trusted name in industrial coatings, supplying high-quality products to customers worldwide. Based in China, we produce a broad spectrum of paints and resins, including epoxy coatings, acrylic paints, alkyd finishes, and nitrocellulose coatings. Our solutions cater to various industries, from construction and petrochemicals to shipbuilding and steel structures. We are committed to providing low-cost, high-quality products with exceptional performance. Buyers can benefit from wholesale pricing, promotional discounts, and flexible customization . If you are looking for a reliable supplier or manufacturer, contact Huaren Chemical today to discuss your purchasing requirements!